The all-ceramic thermal mass flow probe can be used in a wide range of industrial applications such as water, chemicals, oils and slurry mass flow measurement. To correct for thermal conductivity of the medium, the mass flow meter is embedded in the slurry density analyser or the chemical concentration analyser.

The probe is heated up a few degrees above the medium temperature. More heat is absorbed by the liquid when the thermal conductivity increases or when the flow velocity increases. The heat transfer coefficient is a function of, for example, viscosity, Reijnolds numbers and the mass flux. This function is set in a single point field calibration. Dividing this mass flux by the ultrasonic slurry density or the concentration of the chemical, the velocity of the medium is accurately determined in m/s. It appears that this technology is more accurate and reproducible than other flow meters in the world.

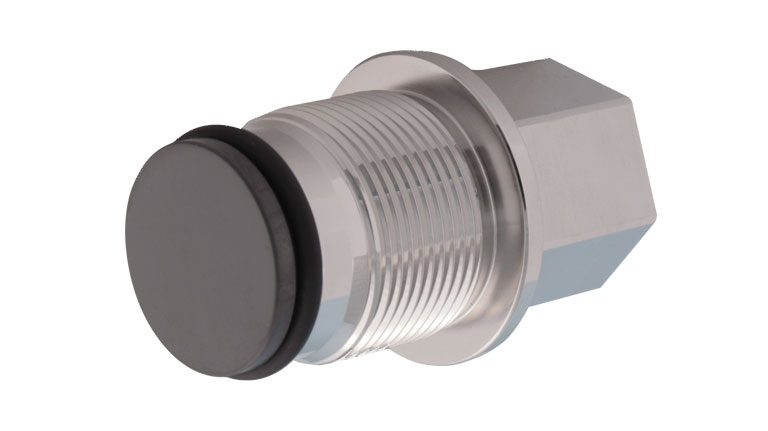

All ceramic probes from Arenal are designed to fit in abrasive and high massflow slurry applications. The ceramic sensor is made from one of the toughest materials on earth: Silicon Carbide (SiC). They are much more wear resistant compared to all other ceramics. Secondly the acoustical, thermal and physical properties of SiC are perfect for the applications in abrasive slurry massflow monitoring.

Français

Français  Español

Español  简体中文

简体中文  Arabic

Arabic