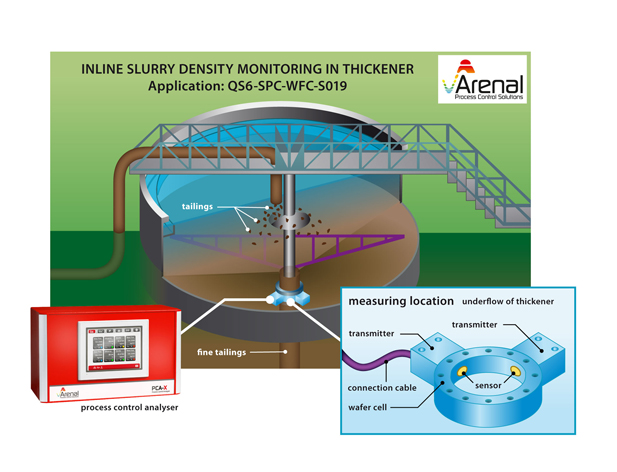

Arenal PCS produces Slurry Density Analysers for the mining, dredging, drilling industry and for building materials. The Analyser consists of the process control Analyser and the wafer with its sensors. The wafer is connected between two flanges in such way that the ceramic sensors are flush mounted in the mass stream. Arenal is the first and only supplier in the world of ultrasonic density Analysers and slurry transmitters with ceramic sensors: they do not wear, respond fast, are highly reproducible, inline and can withstand high pressures and temperatures.

Some points of use in the industry

- Mining slurry density, like for magnetite slurry, gold slurry, copper slurry, coal slurry

- Dredging slurry density, sucking line also submersible slurry density monitoring

- Drilling mud preparation and flow line

- Cement, concrete and grout slurry density

Technology

Ultrasonic spectroscopy is the better and safer alternative for nuclear densitometers. High energy pulses are induced into the piezo element: an ultrasonic wave arises and propagates through the ceramic elements: the reflections from the the interface between the element and the slurry are measured. Their properties change due to the temperature and the properties of the slurry, of which density is one of. All acoustic properties are read by the process control Analyser (PCA). In the PCA the density, SG, and temperature are calculated. Learn more about the technology here.

Embodiments

One or more ceramic probes can be mounted in wafer cells, made from high molecular weight polyethylene-1000. The size of the wafer is depending on the pipe and flange size.

Contact us for more information with our contact form or our inquiry form.

Français

Français  Español

Español  简体中文

简体中文  Arabic

Arabic